Page 223 - Water Standards

P. 223

3) The stroke switch shall move sensitively and reliably.

4) For screw headstock gear with load control and height indicating devices, special

tests shall be done to check the sending and receiving of the sensor signal in order

to ensure that the mechanism can move sensitively and indicate correctly, safely

and reliably.

5) For headstock gear with dual lifting points, synchronous lifting up and lowering

down shall have no blockage.

6) The operation of the electric motor shall be steady and the transmission belt shall

have no slippage phenomenon

4 1 16 Installation of the embedded penstock shall meet the following requirements:

1 The penstock supporters shall have enough strength and stability to ensure the pen⁃

stock has no displacement and deformation during installation

2 The allowable installation error of the embedded penstock centerline shall meet the

requirements of Table 4 1 16-1. The mileage deviation of starting segment shall be no larger

than ±5mm and no larger than ±10mm for the elbow starting point. The perpendicularity de⁃

viation of the starting segment orifice shall be no larger than ±3mm

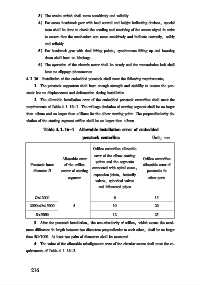

Table 4 1 16-1 Allowable installation error of embedded

penstock centerline Unit: mm

Orifice centerline allowable

error of the elbow starting

Allowable error Orifice centerline

points and the segments

Penstock inner of the orifice allowable error of

connected with spiral cases,

diameter D center of starting penstocks in

expansion joints, butterfly

segment other parts

valves, spherical valves

and bifurcated pipes

D≤2000 6 15

2000<D≤5000 5 10 20

D>5000 12 25

3 After the penstock installation, the non⁃circularity of orifice, which means the maxi⁃

mum difference in length between two diameters perpendicular to each other, shall be no larger

than 5D/ 1000. At least two pairs of diameters shall be measured

4 The value of the allowable misalignment error of the circular seams shall meet the re⁃

quirements of Table 4 1 16-2

2 1 6