Page 244 - Water Standards

P. 244

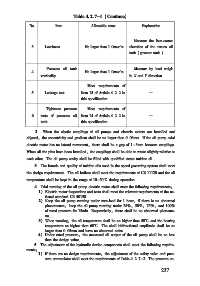

Table 4 2 7-1 (Continue)

No Item Allowable error Explanation

Measure the four⁃corner

3 Levelness No larger than 1 0mm/ m elevation of the return oil

tank (govenor tank )

Pressure oil tank Measure by lead weigh

4 No larger than 1 0mm/ m

verticality in X and Y direction

Meet requirements of

5 Leakage test Item 15 of Article 4 2 2 in —

this specification

Tightness pressure Meet requirements of

6 tests of pressure oil Item 14 of Article 4 2 2 in —

tank this specification

2 When the elastic couplings of oil pumps and electric motors are installed and

aligned, the eccentricity and gradient shall be no larger than 0 08mm. If the oil pump axial

electric motor has no lateral movement, there shall be a gap of 1-3mm between couplings.

When all the pins have been installed, the couplings shall be able to rotate slightly relative to

each other. The oil pump cavity shall be filled with qualified steam turbine oil

3 The brands and quality of turbine oils used in the speed governing system shall meet

the design requirements. The oil indices shall meet the requirements of GB 11120 and the oil

temperature shall be kept in the range of 10-50℃ during operation

4 Trial running of the oil pump electric motor shall meet the following requirements:

1) Electric motor inspections and tests shall meet the relevant requirements of the na⁃

tional standard GB 50150.

2) Keep the oil pump running under zero⁃load for 1 hour, if there is no abnormal

phenomenon, keep the oil pump running under 25%, 50%, 75%, and 100%

of rated pressure for 15min. Respectively, there shall be no abnormal phenome⁃

na.

3) When running, the oil temperature shall be no higher than 50℃ and the bearing

temperature no higher than 60℃ . The shell bidirectional amplitude shall be no

larger than 0 05mm and have no abnormal noise.

4) Under rated pressure, the measured oil output of the oil pump shall be no less

than the design value.

5 The adjustment of the hydraulic device components shall meet the following require⁃

ments:

1) If there are no design requirements, the adjustment of the safety valve and pres⁃

sure annunciator shall meet the requirements of Table 4 2 7-2. The pressure an⁃

2 3 7